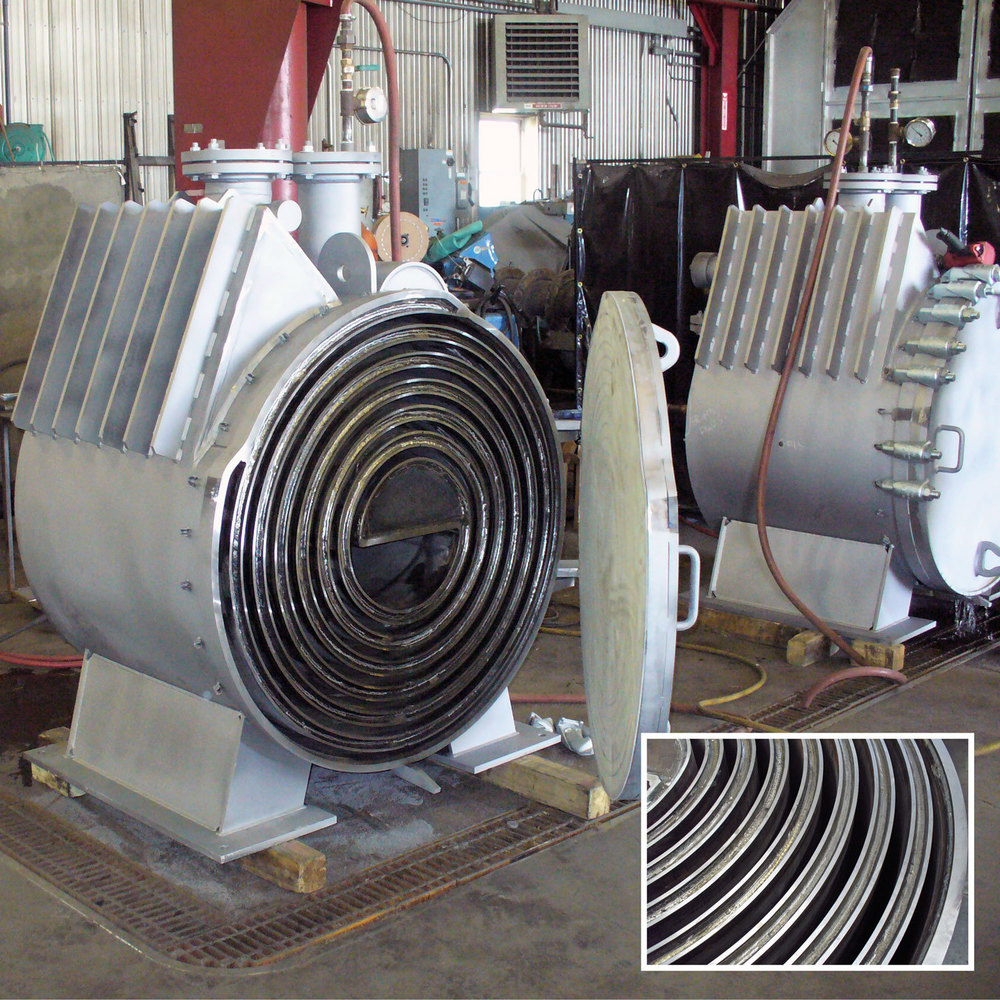

Plate heat exchangers are known as sorts of warmth exchangers that make utilization of a metal plate particularly whilst exchanging heat between two sorts of liquids. It is being utilized as a part of a wide exhibit of utilizations including sustenance preparing, aerating and cooling and refrigeration frameworks, administration warming and cogeneration, seaward gas and oil applications and in addition substance processing. These exchangers are likewise exceptionally prominent in different commercial enterprises, for example, marine, assembling and materials handling.

This is for you to set up its distinction with different sorts offered in the business sector. All things considered, there are five principle points of interest to consider.

Advantages of utilizing plate heat exchangers

Remarkably, this sort of warmth exchanger has effectively become famous in the business sector. At the point when contrasted with ordinary ones, these are favored by clients fundamentally in light of the fact that warmth spreads in a bigger surface region since the fluid goes on to the plate. Beside this conspicuous attribute, there is considerably more this device can offer.

- Minimization. The latest adaptations are little. As a result of this, they possess a base measure of floor space. Regardless of this, general warmth exchange is higher.

- Adaptability. This is viewed as another extraordinary advantage. Its adaptability implies that you can utilize an assortment of liquids in addition to you are permitted to alter it as indicated by particular conditions most reasonable for your business. Subsequently, it will likewise be less demanding for you to pick the outline you need for this device.

- Controllable temperature. A plate heat exchanger has the ability to work as per lower temperatures. This implies you don’t need to stress over dealing with high temperatures. Thusly, you will never have an issue with overheating and in addition stagnant zones.

- Low support. Some of you would prefer not to invest much energy cleaning your warmth exchangers. This can be an overwhelming undertaking on your part particularly on the off chance that you require the plates for sustenance handling purposes. With this write, you don’t need to stress much when cleaning time comes. Just destroy its distinctive segments then assess every part before cleaning them. Likewise, you can without much of a stretch expel and supplant the plates when required.

- Ease. Contributing on plate heat exchangers is made less demanding for every industry in light of its low creation cost. These are fundamentally made out of squeezed plates that are said to be less expensive when contrasted with welded plates. Squeezed plates are likewise said to be ideal since they are consumption safe.

Plate heat exchangers are to be sure should be perceived in the business sector. With the wide cluster of advantages it can offer, you will definitely consider contributing on such things for your business. On top of all the considerable things specified about these warmth exchangers, recollect that you may even modify them to fit your business’ needs.